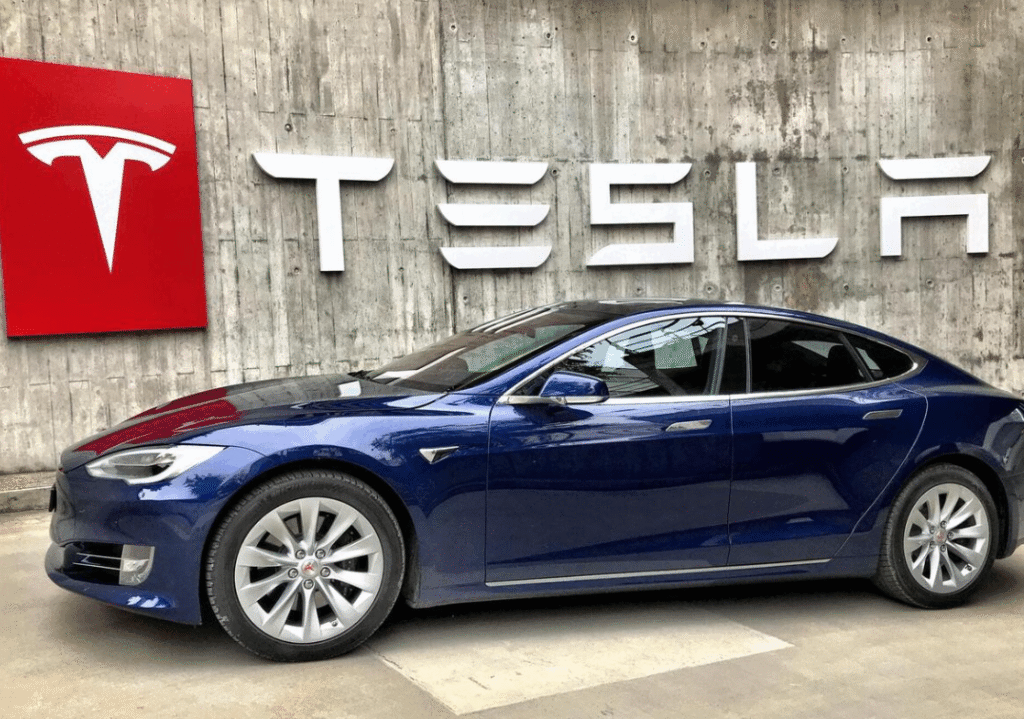

Tesla: How Vertical Integration Redefined the Global Automotive Business

Tesla has never operated like a traditional automotive company. While legacy car manufacturers rely heavily on third-party suppliers, dealerships, and fragmented production chains, Tesla chose a radically different path. By embracing vertical integration, Tesla redefined how vehicles are designed, manufactured, sold, and updated.

This strategic decision not only disrupted the global automotive industry but also positioned Tesla as one of the most influential companies of the 21st century. This article explores Tesla’s vertical integration strategy and how it reshaped the future of mobility.

Understanding Vertical Integration in the Automotive Industry

Vertical integration refers to a business strategy where a company controls multiple stages of its value chain—from raw materials to final sales and after-sales services.

Traditionally, automakers:

- Outsource key components

- Rely on dealer networks

- Separate software from hardware development

Tesla challenged this model by internalizing critical operations, allowing it to move faster, innovate more aggressively, and retain greater control over quality and costs.

Tesla’s Control Over Manufacturing

Tesla designs and manufactures many of its core components in-house, including:

- Electric motors

- Battery packs

- Power electronics

- Vehicle software

Gigafactories are central to this strategy. These massive facilities integrate battery production, vehicle assembly, and software deployment under one roof.

Business impact:

By reducing supplier dependency, Tesla lowered production bottlenecks and accelerated innovation cycles.

Battery Technology as a Strategic Advantage

Batteries are the most expensive and critical component of an electric vehicle. Tesla’s early investment in battery research and production gave it a significant competitive edge.

Key moves include:

- In-house battery design

- Partnerships with controlled manufacturing oversight

- Development of proprietary battery cells

This vertical control allowed Tesla to improve energy density, reduce costs, and scale production faster than competitors.

Software Integration: Tesla’s Secret Weapon

Unlike traditional automakers, Tesla treats vehicles as software platforms.

Tesla develops:

- Operating systems

- Autonomous driving software

- Over-the-air update infrastructure

This integration enables Tesla to push performance upgrades, safety improvements, and new features remotely—long after a car is sold.

Strategic advantage:

Software-driven vehicles extend product life cycles and strengthen customer loyalty.

Direct-to-Consumer Sales Model

Tesla bypassed the traditional dealership model, selling directly to consumers through online platforms and company-owned stores.

Benefits of this approach include:

- Full control over pricing

- Consistent brand experience

- Direct customer data access

This model aligns seamlessly with Tesla’s vertically integrated philosophy, removing intermediaries and increasing operational efficiency.

Supply Chain Resilience and Cost Control

Vertical integration proved especially valuable during global supply chain disruptions. While many automakers faced production halts, Tesla adapted quickly by:

- Rewriting software to use alternative chips

- Adjusting internal manufacturing processes

- Reducing reliance on external vendors

Business lesson:

Control over the value chain increases resilience during economic and geopolitical shocks.

Risks and Challenges of Tesla’s Strategy

Vertical integration is not without risks. Tesla faces:

- High capital expenditure

- Operational complexity

- Increased execution pressure

However, Tesla mitigates these risks through scale, automation, and continuous innovation.

How Tesla Redefined the Global Automotive Business

Tesla’s success forced the automotive industry to rethink long-standing practices. Today, major manufacturers are:

- Investing in in-house software teams

- Building battery factories

- Reducing dealership dependency

Tesla didn’t just build electric cars—it redefined what an automotive company can be.

Conclusion

Tesla’s vertical integration strategy transformed the global automotive business by breaking away from outdated manufacturing and sales models. By controlling technology, production, software, and customer relationships, Tesla created a powerful competitive advantage that continues to shape the future of transportation.